PROJECTS

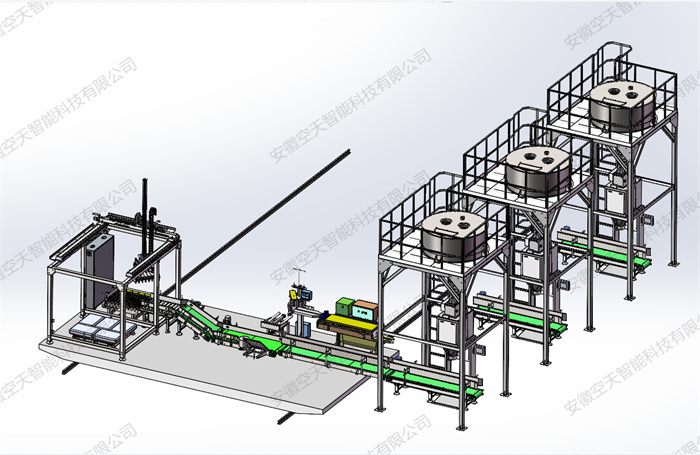

Typical case site of automatic weighing, packaging and palletizing system

The customer’s plastic particles are high-end materials, with high prices and high precision; We choose KTSAHQ-25 series high-precision semi-automatic packaging machine, the packaging accuracy can reach within 10g; Cooperate with the automatic bagging machine KTGS-DA series bagging machine to complete the automatic packaging machine;

The sealing requires kraft paper bags to be wrinkled paper seams; We chose Japan Newland DS-7C sealing machine to complete the folding machine; The failure rate is almost zero;

The packaging machine is connected with the front-end homogenization silo and the vacuum feeder, and we have designed a high and low material level alarm system, and reserved an RS485 communication module;

The project site restrictions require as much space as possible, and we adopt the concept of double-line convergence to save the greatest space;

The project requires a robot to palletize second-line products at the same time, and supporting the second-line automatic pallet warehouse system; We have designed a long-span base to convey empty pallets from under the robot base for maximum space saving

Typical case site of semi-automatic weighing, packaging and palletizing system

The customer’s plastic particles are high-end materials, with high prices and high precision; We choose KTSA-HQ25 series high-precision semi-automatic packaging machine, the packaging accuracy can reach within 10g;

When weaving bags, folding and sewing are required, and when enveloping bags, heat sealing and folding are required; We used a removable hem sewing bag and a special glued folding and heat sealing seal for envelope bags

The project site constraints require space saving as much as possible, and we have designed a lifting conveyor on the intermediate palletizing conveyor line to replace the traditional climbing conveyor, which shortens the overall space by 1 meter;

4: The project requires a robot to palletize three-line products at the same time, and is equipped with a three-line automatic pallet warehouse system; We designed a large-span base, and the empty pallet conveyor passes under the robot base to save the greatest space, and at the same time, due to the large span of three-line simultaneous palletizing, we chose a robot with a working radius of 3150mm;

Mobile palletizing workstation project case site

The overall movable platform includes a sealing system unit, a palletizing conveying shaping unit, and a palletizing unit;

The trolley line of the mobile platform adopts the antenna rail; The layout is beautiful;

The palletizer adopts KTSR-Z400 series Cartesian coordinate palletizer, which is fixed on the mobile platform, which is safe and stable;

Compared with robot palletizing and fixed palletizing, the whole project can save a lot of cost in multi-line packaging and palletizing, and there is only one set of sealing equipment and palletizing lines;

The difficulty of the whole project lies in the project design and on-site construction, the project is a non-standard design, the layout and connection must be accurate, and the construction experience is very important for the successful implementation of such projects